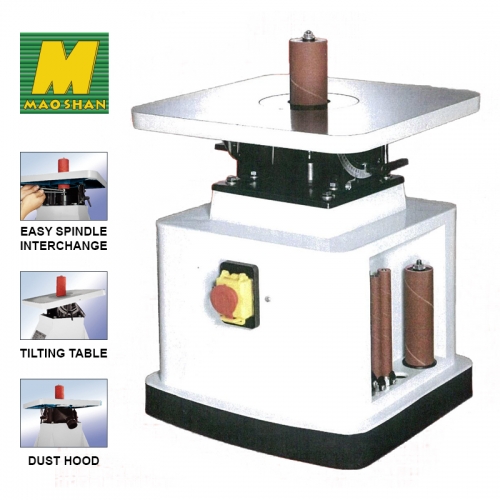

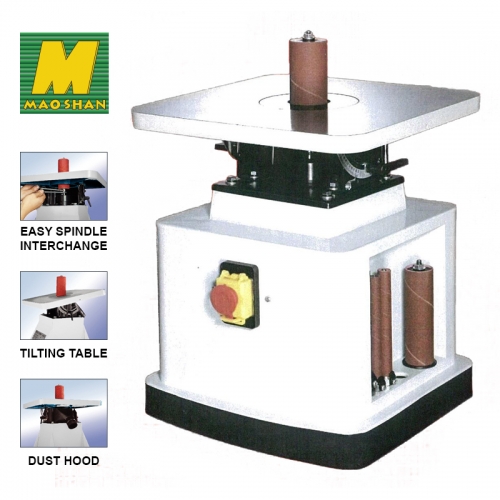

HHM Oscillating Spindle Sander OVS-TG

Features:

1. 370x370mm Cast iron table, rib reinforced for maximum stability. The table surface is precision ground.

2. Heavy gauge steel frame.

3. Rubber drum can be fitted on both ends for full use of the entire spindle.

4. The high spindle speed of 1720RPM combined with the oscillating fine finishing effects.

5. Easily interchangedable spindle.

6. Tilting table for bevelled parts sanding.

Easy Spindle Interchange

This machine accepts spindle diameters of 1/4″, 1/2″ and 3/4″ for fitting with various diameters of rubber drum.

Spindle change is easily made using the wrench supplied.

Tilting Table

The table may be tilted front downwards up to a maximum of 45 degrees to allow the sanding of bevelled parts.

A graduated scale is attached for accurate reading of the degree of tilt.

DUST HOOD

A plastic dust hood is supplied under the table for connection to a dust collector.

The dust hood outlet diameter is 2″.

Technical Specification:

| MODEL | OVS-TG |

|---|---|

| Oscillations per minute | 100 |

| Oscillations stroke | 15/16″ (24 mm) |

| Sanding spindle diameter (Sandard) | 1/4″, 1/2″, 5/8″, 1-1/2″, 2″ |

| Sanding spindle diameter (Optional) | 3″ |

| Spindle speed | 1720 rpm |

| Table area | 370 x 370 mm |

| Table tilt | 45 degrees front, downward |

| Table height from floor | 465 mm |

| Motor | 1/2 HP |

| Dust hood outlet diameter | 2″ |

| Net weight | 30.3 kgs |

| Gross weight | 37.7 kgs |

| Machine dimensions (LxWxH) | 370 x 370 x 480 |

| Packing dimensions (LxWxH) | 435 x 435 x 525 |

* All specifications, dimensions and design characteristics shown are subject to change without prior notice.

Spindle Sanders

Using a spindle sander is the best way to sand curved edges and other shaped woodwork. These machines are ideal for smoothing complex surfaces, such as the inside edges of concave curves.

Spindle sanders use replaceable spindles, or bobbins, for the sanding operation.

Spindles are available in a range of sizes depending on the job.

To increase the life of the abrasive paper, some machines have a spindle that oscillates vertically, spreading the wear over the length of the spindle.

Keep moving the workpiece to avoid grooves from forming due to over-sanding.